Web Menu

Product Search

Exit Menu

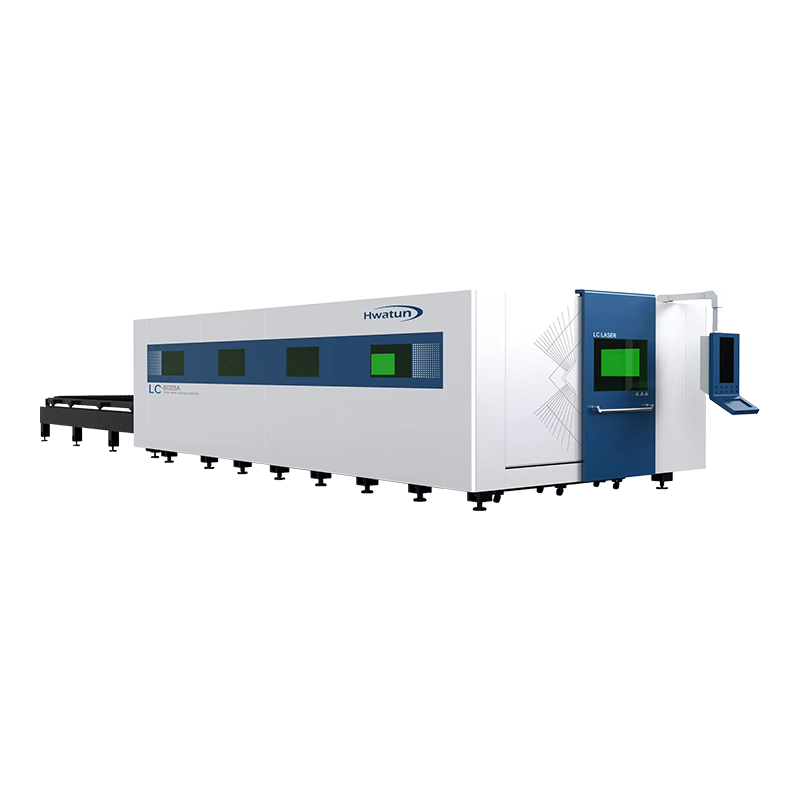

How can CNC Laser Cutting Machine achieve high precision and high efficiency in complex graphics processing applications?

With the continuous improvement of the manufacturing industry's demand for component precision and personalized design, CNC Laser Cutting Machine has become an important tool for processing complex graphics. Its performance in processes such as special-shaped contours, tiny holes, and precision hollowing is particularly outstanding. So, how does this type of equipment achieve high-efficiency production while ensuring high precision?

Technical guarantee for high-precision cutting

To achieve precise processing of complex graphics, we must first rely on the core components of the laser cutting machine:

High-stability laser light source: Modern equipment mostly uses fiber lasers with high beam quality and fine focusing, which can achieve micron-level cutting accuracy;

Optical system optimization: Equipped with high-quality focusing lenses and dynamic focusing functions to ensure that materials of different thicknesses can achieve consistent cutting effects;

High-precision motion control system: Using servo motor + encoder closed-loop control, the positioning accuracy can reach ±0.01mm, supporting the precise execution of complex paths;

CAD/CAM software integration: Supports the import of multiple graphic formats (such as DXF, AI), and improves processing consistency through intelligent path planning.

These technical means work together to enable CNC laser cutting machines to easily cope with the high-precision requirements of complex structures such as curves, sharp angles, and dense patterns.

Ways to achieve high-efficiency production

On the basis of ensuring accuracy, improving production efficiency is the focus of industrial users. CNC laser cutting machines achieve efficient operation through the following methods:

Automatic loading and unloading system: Some models are equipped with automatic feeding platform or double-station exchange system to reduce manual intervention and achieve continuous operation;

High-speed cutting technology: By optimizing pulse frequency and gas-assisted cutting (such as nitrogen and oxygen injection), the cutting time and perforation time are greatly shortened;

Intelligent path optimization: Nesting software automatically arranges multiple graphics to maximize material utilization, while reducing empty strokes and shortening the overall processing cycle;

Multi-axis linkage cutting: X/Y/Z axes work together to support three-dimensional curved surfaces and inclined angle cutting, and improve one-time forming rate.

These designs not only improve the output capacity per unit time, but also reduce the operating threshold and labor costs.

Typical application scenarios

In industries such as advertising logos, electronic hardware, and decorative arts, CNC laser cutting machines perform well:

In the advertising industry, they can quickly complete complex LOGO and hollow text cutting with smooth edges and no burrs;

In electronic manufacturing, they can achieve high-precision processing of parts such as micro connectors and shielding covers;

In the field of art decoration, they are suitable for the production of creative works such as metal carvings and hollow screens.

These scenarios pose dual challenges to precision and efficiency, and CNC laser cutting machines have become an ideal choice with their excellent comprehensive performance.

Maintenance and stability guarantee

To ensure long-term and efficient operation, the equipment must also have good maintenance performance:

Equipped with automatic dust removal and cooling systems to prevent lens contamination and overheating from affecting cutting quality;

Support remote monitoring and intelligent diagnosis, and timely warning of potential faults;

Modular design facilitates the replacement of vulnerable parts and reduces downtime.

The reason why CNC Laser Cutting Machine can balance high precision and high efficiency in complex graphics processing is inseparable from advanced laser technology, intelligent control systems, and efficient production process management. It not only meets the modern manufacturing industry's dual pursuit of product quality and production efficiency, but also provides solid support for personalized customization and flexible manufacturing.

News categories

Product categories

Related Products

+86-159 5138 1316

+86-159 5138 1316 +86 180 6819 3096

+86 180 6819 3096 [email protected]

[email protected] Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Copyright © Nantong Hwatun Heavy Machine Tool Co., Ltd. All Rights Reserved.

Eng

Eng  简体中文

简体中文 Español

Español русский

русский