Web Menu

Product Search

Exit Menu

Is Shearing Machine difficult to maintain?

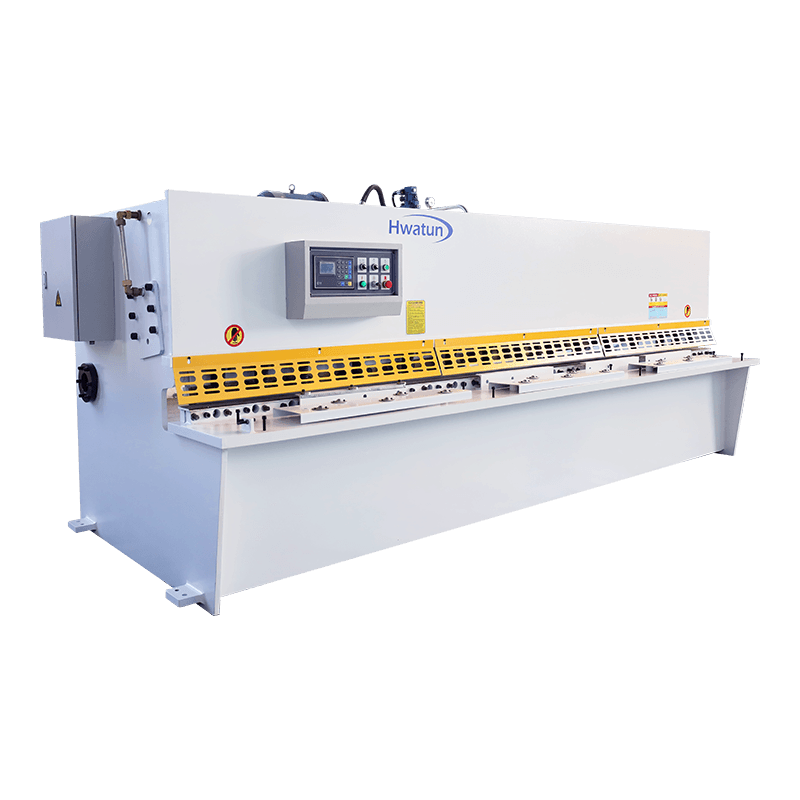

When people invest in industrial equipment such as a shearing machine, one of the most common concerns is maintenance. A shearing machine is a powerful tool used to cut sheet metal with precision, speed, and efficiency. It is widely applied in industries like construction, automotive, shipbuilding, and manufacturing.

Understanding the Basics of a Shearing Machine

Before analyzing the difficulty of maintenance, it is essential to understand the basic structure of a shearing machine. Generally, the machine consists of a frame, blades, hydraulic or mechanical drive systems, holddown devices, and a back gauge for positioning the material. The most common types are hydraulic shearing machines and mechanical shearing machines.

Hydraulic Shearing Machines rely on hydraulic cylinders to power the blades. They offer smooth operation, adjustable pressure, and high accuracy, but their hydraulic systems require careful monitoring.

Mechanical Shearing Machines are simpler in construction, using a flywheel or motordriven system. They are easier to operate but may need more frequent inspection of mechanical parts like gears and belts.

Each type has unique maintenance demands, but neither can be neglected if consistent performance and long lifespan are desired.

Key Maintenance Areas

Maintaining a shearing machine involves paying attention to several crucial areas:

1. Blades

The cutting blades are the heart of the machine. Dull or chipped blades can lead to rough edges, inaccurate cuts, or even machine damage. Regular sharpening and correct blade clearance adjustment are vital.

2. Lubrication

Like any industrial machine, lubrication prevents wear and tear of moving parts. Grease or oil must be applied to bearings, sliding surfaces, and mechanical joints at scheduled intervals.

3. Hydraulic System

For hydraulic shearing machines, checking the oil level, replacing hydraulic fluid periodically, and inspecting hoses and seals for leaks are crucial tasks.

4. Electrical Components

Modern shearing machines often feature electronic control systems. Checking wiring, switches, and sensors ensures smooth and safe operation.

5. Fasteners and Alignment

Bolts, screws, and holddown devices can loosen over time due to vibration. Keeping all components tightly secured and properly aligned prevents performance issues.

Is the Maintenance Process Complicated?

The good news is that shearing machines are not excessively difficult to maintain, but they do require discipline. Let’s look at why.

1. Routine Checks Are Simple

Most maintenance tasks, such as cleaning, lubricating, or checking oil levels, are straightforward and can be performed by operators with basic training.

2. Periodic Professional Servicing

While daytoday care is manageable, professional technicians may be required for blade sharpening, hydraulic system calibration, or complex repairs. However, these services are not needed frequently if the machine is used properly.

3. Preventive Maintenance Is Key

Following a preventive maintenance schedule greatly reduces the chance of unexpected breakdowns. Simple practices like checking blade clearance daily or monitoring hydraulic oil monthly make a big difference.

Factors That Influence Maintenance Difficulty

Whether maintaining a shearing machine feels difficult often depends on the following:

Frequency of Use: A machine used continuously in heavy production will need more frequent servicing than one used occasionally.

Operator Training: Welltrained operators can handle routine maintenance confidently, while untrained staff may find it challenging.

Machine Quality: Highquality machines from reputable manufacturers are usually designed with easier maintenance access and better durability.

Work Environment: Dusty, humid, or dirty environments can accelerate wear, making maintenance more demanding.

Practical Tips to Make Maintenance Easier

1. Keep a Logbook: Recording every maintenance task and inspection helps track performance and anticipate future needs.

2. Use Genuine Spare Parts: Replacing blades or hydraulic components with original parts ensures reliability.

3. Train Operators: Investing in operator training reduces mistakes and improves maintenance efficiency.

4. Maintain Cleanliness: Regularly cleaning the machine and its surroundings minimizes contamination of oil, dust accumulation, and rust formation.

5. Schedule Downtime: Planning maintenance during nonpeak hours avoids production disruption.

LongTerm Benefits of Proper Maintenance

Some businesses hesitate to prioritize maintenance because it takes time and resources. However, ignoring it can lead to expensive repairs, downtime, and even safety risks. In contrast, consistent maintenance offers multiple longterm benefits:

Extended Machine Life: Wellmaintained machines can serve for decades.

Better Cutting Accuracy: Sharp blades and proper alignment ensure precise and highquality cuts.

Lower Operating Costs: Preventing breakdowns saves money on emergency repairs.

Increased Safety: Properly maintained machines reduce the risk of accidents caused by malfunctioning components.

So, is a shearing machine difficult to maintain? The answer is no, not particularly. Maintenance is not overly complex, but it requires consistency, attention to detail, and a commitment to preventive care. With proper training, routine inspections, and occasional professional servicing, maintaining a shearing machine becomes a manageable task.

In short, the difficulty of maintaining a shearing machine is more about discipline than complexity. Businesses that prioritize regular maintenance enjoy smoother operations, longer equipment life, and higher productivity—all of which far outweigh the effort involved.

News categories

Product categories

Related Products

+86-159 5138 1316

+86-159 5138 1316 +86 180 6819 3096

+86 180 6819 3096 [email protected]

[email protected] Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Copyright © Nantong Hwatun Heavy Machine Tool Co., Ltd. All Rights Reserved.

Eng

Eng  简体中文

简体中文 Español

Español русский

русский