Web Menu

Product Search

Exit Menu

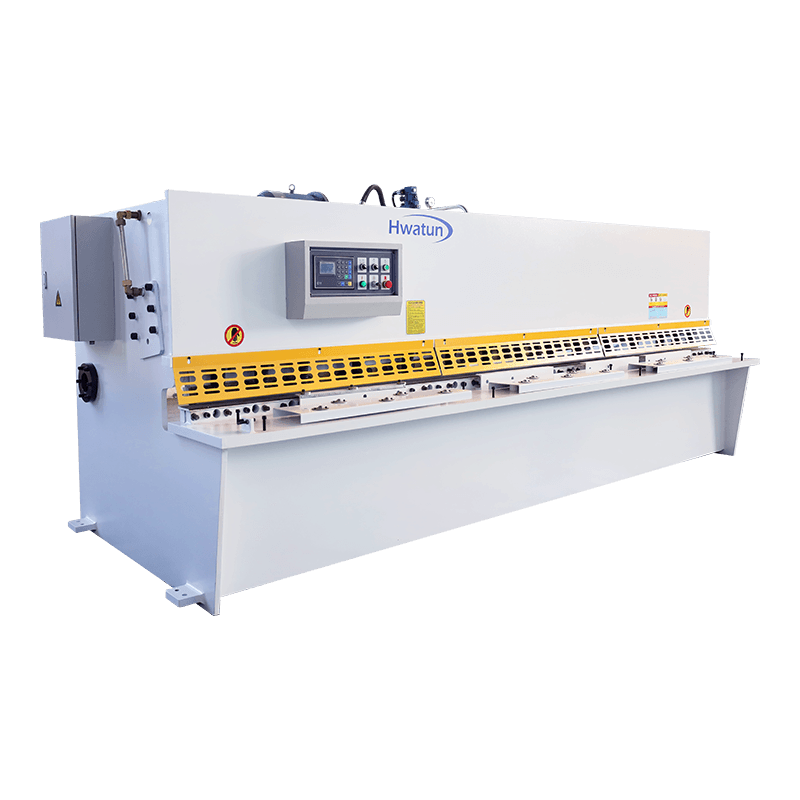

New integrated solution for Shearing Machine systems

1. System architecture design: modular and intelligent integration

The new integrated Shearing Machine system adopts a modular design concept, deeply integrating mechanical structure, electrical control, sensor system and intelligent algorithm. The whole system consists of a shearing host, a servo drive unit, a PLC control system, a human-machine interface (HMI) and a data acquisition and analysis platform. The modules communicate through high-speed buses to achieve efficient information transmission and collaborative control, thereby improving overall operating efficiency and stability.

2. High-precision servo control system: achieving precise shearing

Traditional shearing equipment is mostly driven by hydraulic or ordinary motors, which have problems such as slow response, high energy consumption and low precision. The new system introduces high-performance servo motors as the driving core, combined with encoder feedback technology, to achieve closed-loop control of shearing stroke, speed and pressure. By accurately adjusting the shearing angle and the depth of the knife, the material deformation and edge burrs can be effectively reduced, the shearing quality can be improved, and the precision processing requirements can be met.

3. Intelligent sensing system: real-time monitoring and adaptive adjustment

The system integrates a variety of high-precision sensors, such as displacement sensors, pressure sensors and temperature sensors, for real-time acquisition of key parameters in the shearing process. Through data analysis and processing, the system can automatically identify material thickness, hardness and other characteristics, and dynamically adjust shearing parameters to achieve adaptive shearing. In addition, abnormal conditions can be detected and alarmed in time to avoid equipment damage and production accidents.

4. Human-machine interaction and remote management: improve the convenience and intelligence of operation

Equipped with a touch-type human-machine interface (HMI), users can intuitively set shearing parameters, view operating status and fault information. The system supports multiple language switching and graphical operations to lower the operating threshold. At the same time, the integrated Industrial Internet of Things (IIoT) function realizes remote monitoring, fault diagnosis and maintenance of equipment, improves equipment management efficiency, and helps enterprises build digital workshops.

5. Energy-saving and environmentally friendly design: a new direction for green manufacturing

The new Shearing Machine system fully considers environmental protection and energy-saving factors in its design. The energy-saving servo drive system is adopted, which reduces energy consumption by more than 30% compared with the traditional hydraulic system; optimizes the mechanical structure design to reduce friction loss and noise pollution; and supports automatic collection and classification of waste materials to improve resource utilization, which meets the requirements of green and sustainable development of modern manufacturing industry.

6. Application prospects and market value

The integrated Shearing Machine system is suitable for multiple industries such as automotive parts, home appliance sheet metal, and building steel structures. It is especially suitable for intelligent manufacturing scenarios with high requirements for shearing accuracy and production efficiency. Its highly integrated and intelligent characteristics help companies improve their automation level, reduce labor costs, and improve product quality. It has broad market promotion space and application prospects.

As the manufacturing industry develops towards intelligence and flexibility, traditional shearing equipment can no longer meet the needs of modern production. The introduction of the new integrated Shearing Machine system not only improves shearing accuracy and efficiency, but also realizes intelligent perception, remote management, and green energy saving of equipment, injecting new vitality into the metal processing industry. In the future, with the further integration of artificial intelligence and big data technology, the system will continue to upgrade and promote the shearing process to a higher level.

News categories

Product categories

Related Products

+86-159 5138 1316

+86-159 5138 1316 +86 180 6819 3096

+86 180 6819 3096 [email protected]

[email protected] Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Copyright © Nantong Hwatun Heavy Machine Tool Co., Ltd. All Rights Reserved.

Eng

Eng  简体中文

简体中文 Español

Español русский

русский