Web Menu

Product Search

Exit Menu

What is a Shearing Machine used for?

A shearing machine is a mechanical device used to cut or shear materials—typically sheet metal, plates, or other solid materials—into desired shapes and sizes. It performs this task by applying a high force through a blade that cuts across the material in a straight line. Shearing machines are widely used in industries such as metalworking, manufacturing, construction, shipbuilding, automotive, and aerospace due to their ability to make precise and efficient cuts with minimal material waste.

Types of Shearing Machines

There are various types of shearing machines, each designed for different applications and material thicknesses. The most common include:

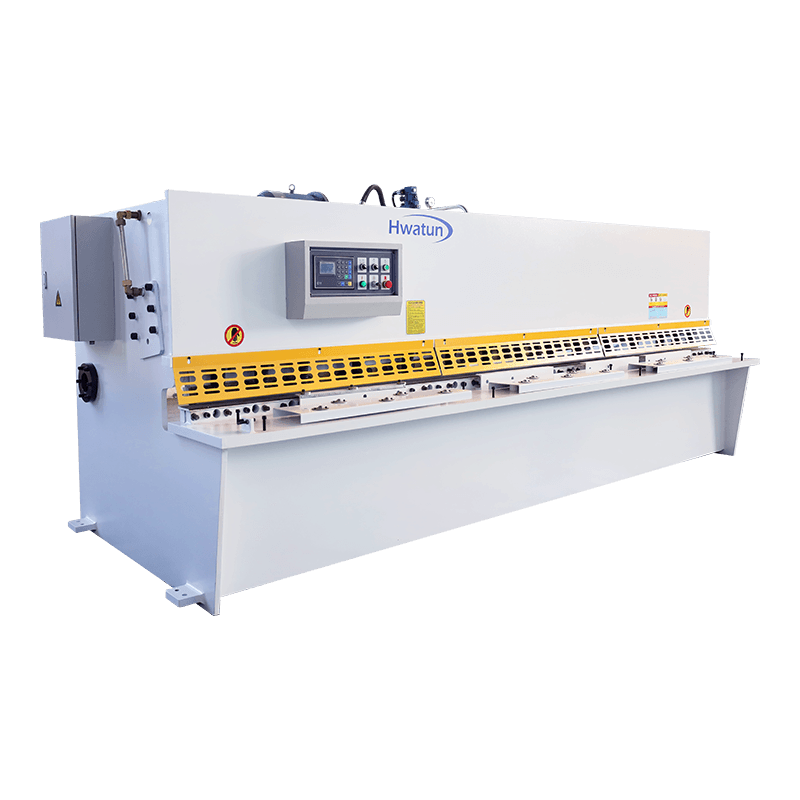

1. Guillotine Shearing Machine:

This machine uses a moving upper blade and a fixed lower blade to cut sheet metal. The material is placed on a worktable and clamped before the blade descends vertically to make the cut. Guillotine shears can be hydraulic or mechanical and are ideal for straight, long cuts.

2. Rotary Shearing Machine:

Equipped with rotating circular blades, this type is typically used for continuous cutting processes. It's suitable for cutting coils of metal or other materials in a production line.

3. Bench Shears or Hand Shears:

These are smaller, manually operated machines often found in workshops. They are used for lighter materials and smaller tasks, offering precision for handcrafted or detailed work.

4. Power Shears:

These machines use electric or pneumatic power to shear metal and are useful for mediumsized operations. They offer more speed and efficiency than manual shears.

Key Functions and Applications

The primary purpose of a shearing machine is to cut sheet metal without the formation of chips or the use of burning or melting. The process is quick and leaves a clean, straight edge, making it ideal for:

Cutting sheet metal to size in fabrication shops

Trimming edges of metal sheets for further processing

Preparing materials for welding or forming

Manufacturing components for machines, vehicles, and buildings

Cutting nonmetal materials like plastic or rubber in some cases

Advantages of Using Shearing Machines

1. Efficiency:

Shearing machines can cut large sheets of material quickly and accurately, improving production rates and reducing manual labor.

2. Clean Cuts:

The cutting action is smooth and leaves minimal burrs, which reduces the need for additional finishing processes.

3. Low Material Waste:

Unlike other methods such as sawing or laser cutting, shearing produces little to no waste, which is costeffective and environmentally friendly.

4. Versatility:

Shearing machines can handle a wide range of materials and thicknesses, making them versatile tools in any fabrication environment.

5. Low Maintenance:

Most shearing machines have few moving parts and are built for durability, requiring less frequent maintenance than more complex cutting systems.

Safety and Automation

Modern shearing machines are often equipped with safety features such as guards, emergency stops, and light curtains to protect operators. Automated controls like CNC (Computer Numerical Control) systems are also commonly integrated, allowing for precise cuts, programmable settings, and repeatable processes, which greatly enhance productivity and accuracy.

A shearing machine is an essential tool for cutting sheet materials in a fast, efficient, and precise manner. Its simplicity, combined with powerful performance and minimal material waste, makes it a staple in industrial and manufacturing settings. Whether for largescale production or detailed custom work, shearing machines provide a reliable and economical solution for material cutting needs.

News categories

Product categories

Related Products

+86-159 5138 1316

+86-159 5138 1316 +86 180 6819 3096

+86 180 6819 3096 [email protected]

[email protected] Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Copyright © Nantong Hwatun Heavy Machine Tool Co., Ltd. All Rights Reserved.

Eng

Eng  简体中文

简体中文 Español

Español русский

русский