Web Menu

Product Search

Exit Menu

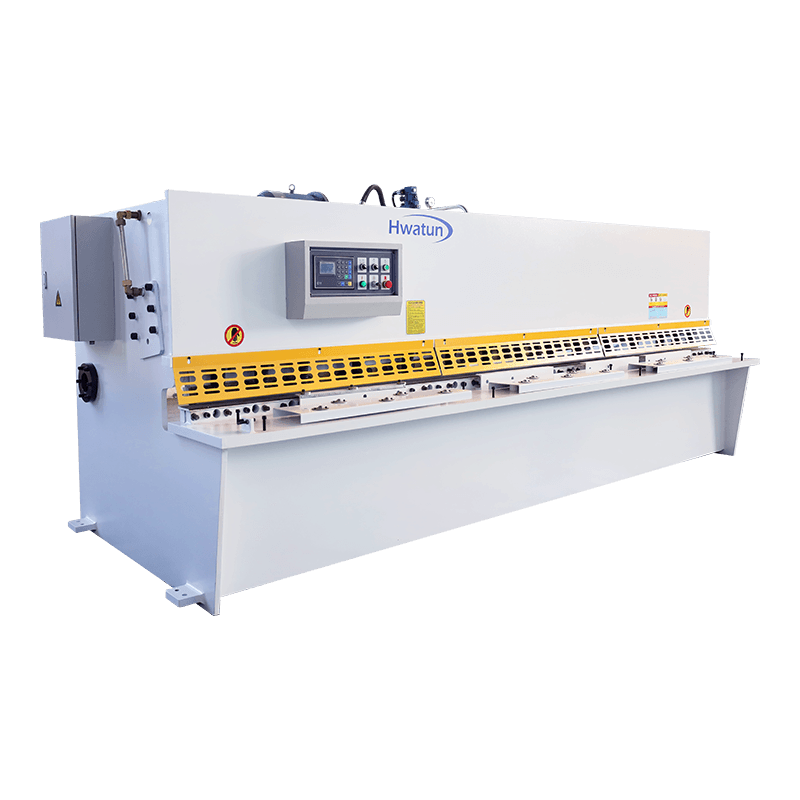

How to improve shearing quality and stability by optimizing Shearing Machine?

To improve the shearing quality and operation stability of the shearing machine, the key lies in systematic optimization from multiple dimensions such as structural design, control system, tool technology, material adaptability and use and maintenance. The following are specific optimization ideas and measures:

First, starting from the mechanical structure design is the basis for improving stability. The overall rigidity of the shearing machine directly determines whether vibration, offset or structural deformation will occur during the shearing process. Optimization methods include thickening the bed steel plate, using box-type structure support, improving the matching accuracy between the slider and the guide rail, and using one-piece welding + annealing to eliminate stress. These can significantly enhance the shear resistance and long-term stability of the equipment.

Secondly, the optimization of the blade and tool holder system is crucial. High-quality shearing must rely on sharp, wear-resistant, and anti-chipping blade materials, such as high-speed tool steel (HSS), tungsten steel or special alloy steel, and combined with precision heat treatment technology. The tool holder needs to be designed as a structure that can fine-tune the angle and gap, especially when processing plates of different thicknesses and materials. Fine-tuning the shear angle and blade gap can effectively reduce burrs, indentations and plate deformation.

Third, the response accuracy and stability of the hydraulic system or servo control system directly affect the repetitive consistency of the shearing process. A high-performance hydraulic system must have constant pressure output, stable locking and flow adjustment capabilities, and be equipped with pressure compensation and temperature control modules. If it is a servo shearing machine, a high-responsive servo motor and a closed-loop feedback control system must be used to ensure that the shearing point is accurately synchronized during high-speed shearing.

On this basis, the improvement of the pressing system is also a key factor in improving the shearing quality. If the plate is warped or slipped before shearing, it will directly affect the accuracy and edge quality of the shearing line. Therefore, the use of a multi-point pressing system (such as a hydraulic pressing cylinder and automatic pressure distribution control) can ensure uniform pressing force while avoiding plate movement and improving the straightness and neatness of the shearing edge.

The introduction of vibration control and automatic blade gap adjustment system is a manifestation of the further improvement of stability of high-end shearing machines. When shearing in large quantities, real-time adjustment of the blade gap and shear angle can dynamically optimize the shearing parameters according to the thickness and material of the plate, avoiding the reduction of incision quality due to human adjustment errors.

In addition, attention should also be paid to the design optimization of the lubrication system and daily maintenance mechanism. The automatic lubrication system can extend the service life of the guide rails and sliding parts and prevent gap changes caused by dry friction. The formulation of standardized maintenance cycles and intelligent diagnostic systems can also provide early warning of equipment aging and deviations to ensure long-term stable operation.

Finally, at the system integration level, digital management of process parameters through PLC or industrial computer control systems can effectively reduce human intervention errors. Combined with functions such as touch interface, blade life monitoring, shearing number statistics, and plate identification system, the uncertainty factors in the equipment shearing process can be minimized and the overall shearing quality can be significantly improved.

Through structural reinforcement, tool upgrades, control accuracy improvement, material pressing and gap optimization, and systematic optimization of digital management methods, not only can the shearing quality of the shearing machine be significantly improved, but also the stability of equipment operation under long-term use can be ensured. This systematic improvement is particularly critical for high-end manufacturing and high-strength material processing scenarios.

News categories

Product categories

Related Products

+86-159 5138 1316

+86-159 5138 1316 +86 180 6819 3096

+86 180 6819 3096 [email protected]

[email protected] Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Copyright © Nantong Hwatun Heavy Machine Tool Co., Ltd. All Rights Reserved.

Eng

Eng  简体中文

简体中文 Español

Español русский

русский