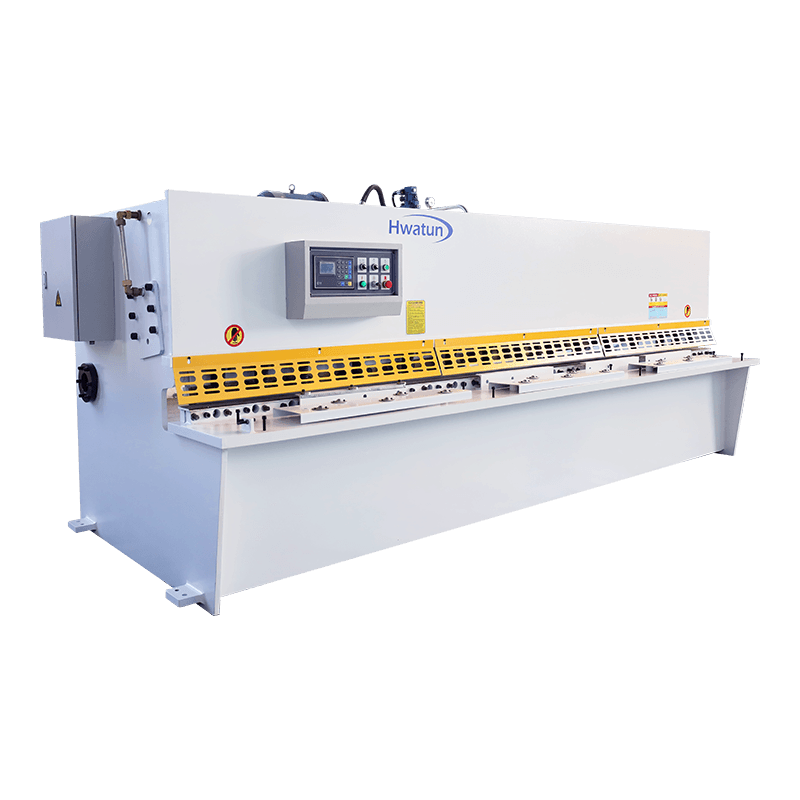

What kind of maintenance does the shearing machine require?

Maintaining a shearing machine is crucial for ensuring its optimal performance, safety, and longevity. Regular maintenance tasks typically include:

Inspection and Cleaning:

Regularly inspect the machine for signs of wear, damage, or misalignment.

Clean the machine and its components to prevent buildup of debris and contaminants that can affect performance.

Blade Maintenance:

Check the blades for sharpness and alignment. Dull or misaligned blades can cause poor cutting quality and increase strain on the machine.

Sharpen or replace blades as needed.

Lubrication:

Lubricate moving parts, such as bearings, gears, and hydraulic components, according to the manufacturer’s recommendations.

Ensure that lubrication is applied evenly and that excess is removed to avoid contamination.

Hydraulic System Checks:

Inspect hydraulic fluid levels and top up if necessary.

Check for leaks in the hydraulic system and address any issues promptly.

Electrical System Maintenance:

Inspect electrical components, such as wiring, switches, and sensors, for signs of damage or wear.

Test safety features and emergency stop buttons to ensure they are functioning correctly.

Calibration and Adjustment:

Regularly calibrate the machine to maintain precision and accuracy in cutting operations.

Adjust settings, such as blade gaps and cutting angles, to ensure proper operation.

Structural Checks:

Inspect the machine’s frame and structural components for signs of wear, cracks, or other damage.

Tighten any loose bolts or fasteners.

Training and Procedures:

Ensure operators are trained in proper machine use and maintenance procedures.

Follow the manufacturer's recommended maintenance schedule and procedures.

Record Keeping:

Keep detailed records of maintenance activities, including dates, tasks performed, and any issues encountered. This helps track the machine’s condition and maintenance history.

Regular maintenance helps prevent unexpected breakdowns, extends the machine’s lifespan, and ensures safe and efficient operation.

Eng

Eng  简体中文

简体中文 Español

Español русский

русский